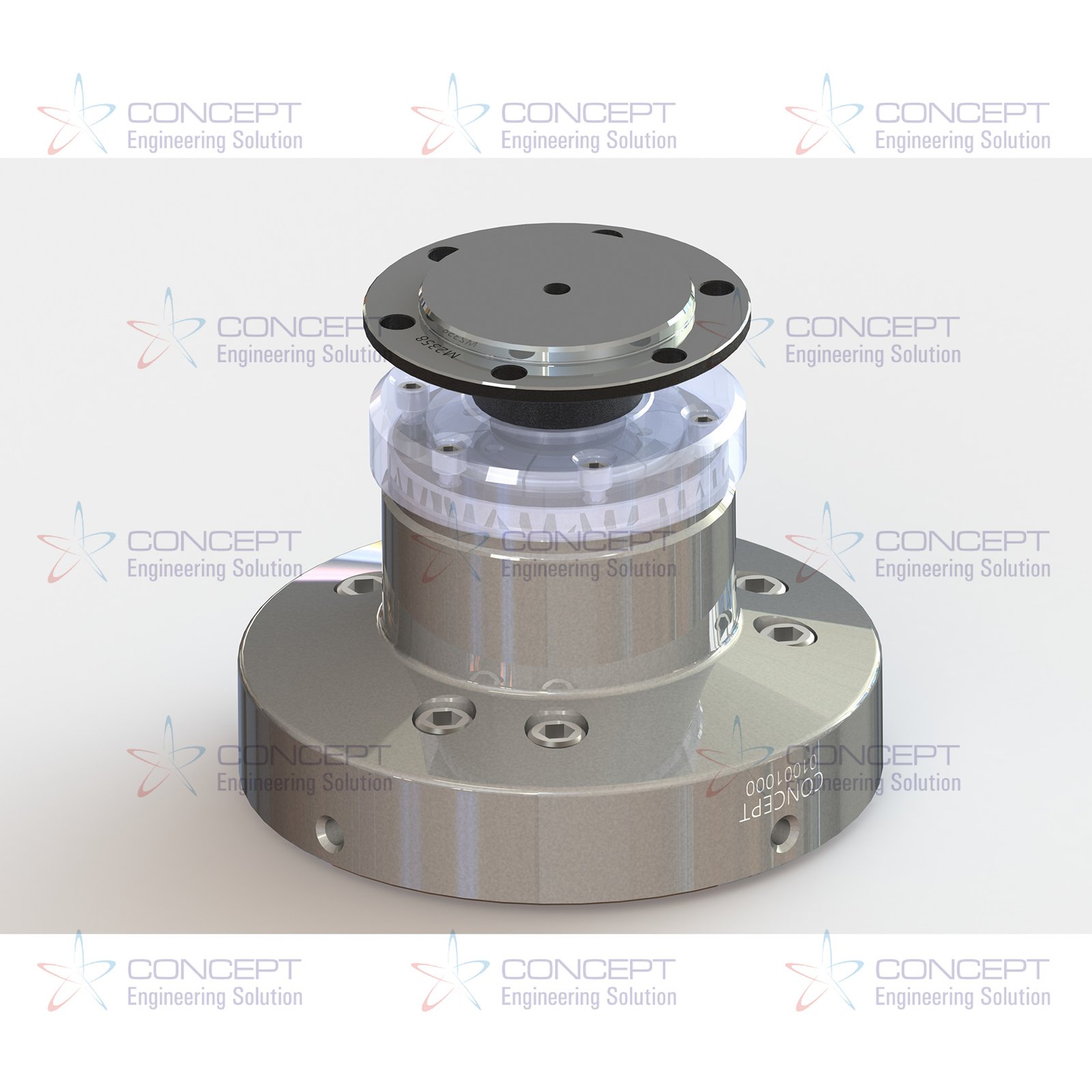

BIG-COLLET

BIG-COLLET

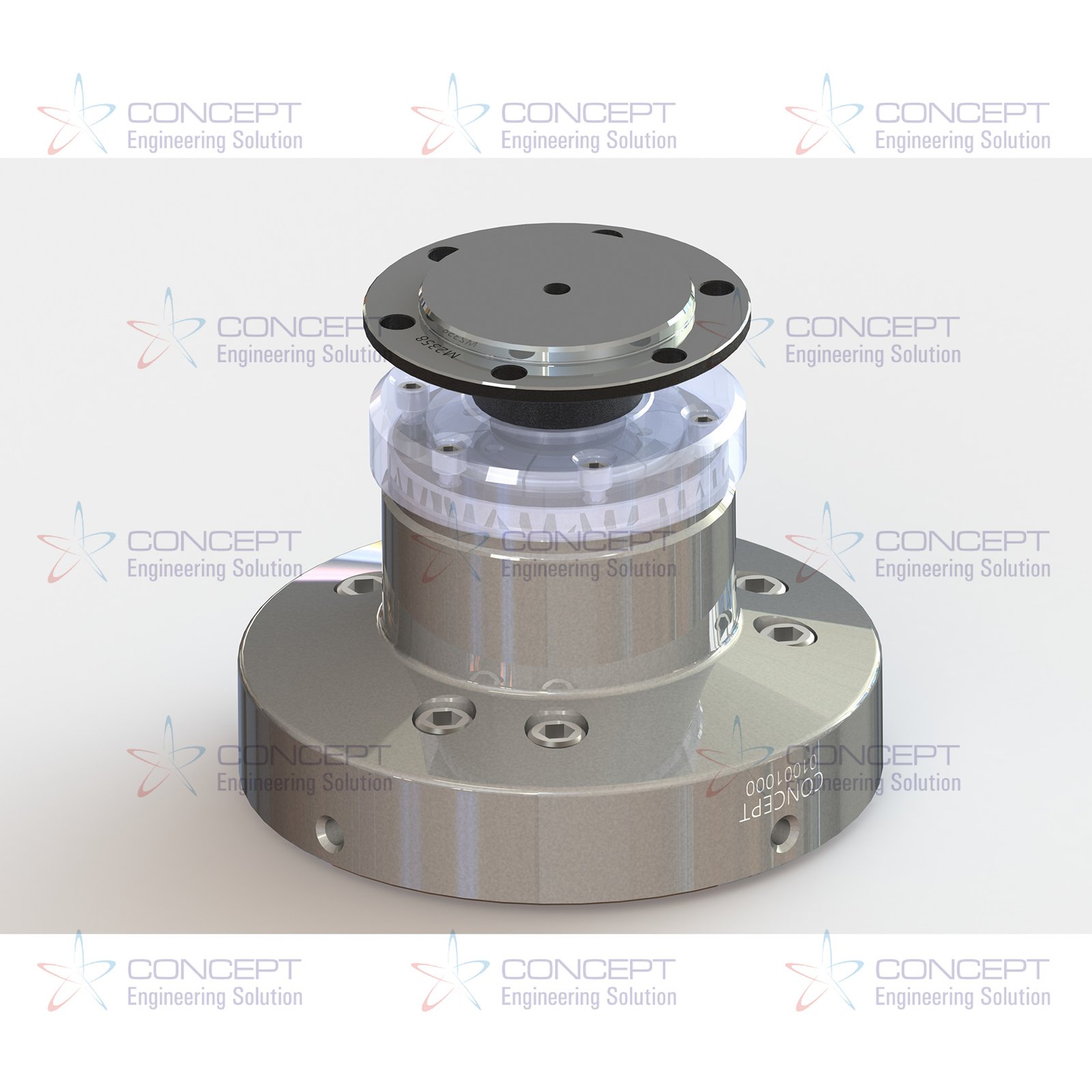

BIG-COLLET-WITH-COMPONENT

BIG-COLLET-WITH-COMPONENT

OD-JELLY-COLLET

OD-JELLY-COLLET

ID-JELLY-COLLET

ID-JELLY-COLLET

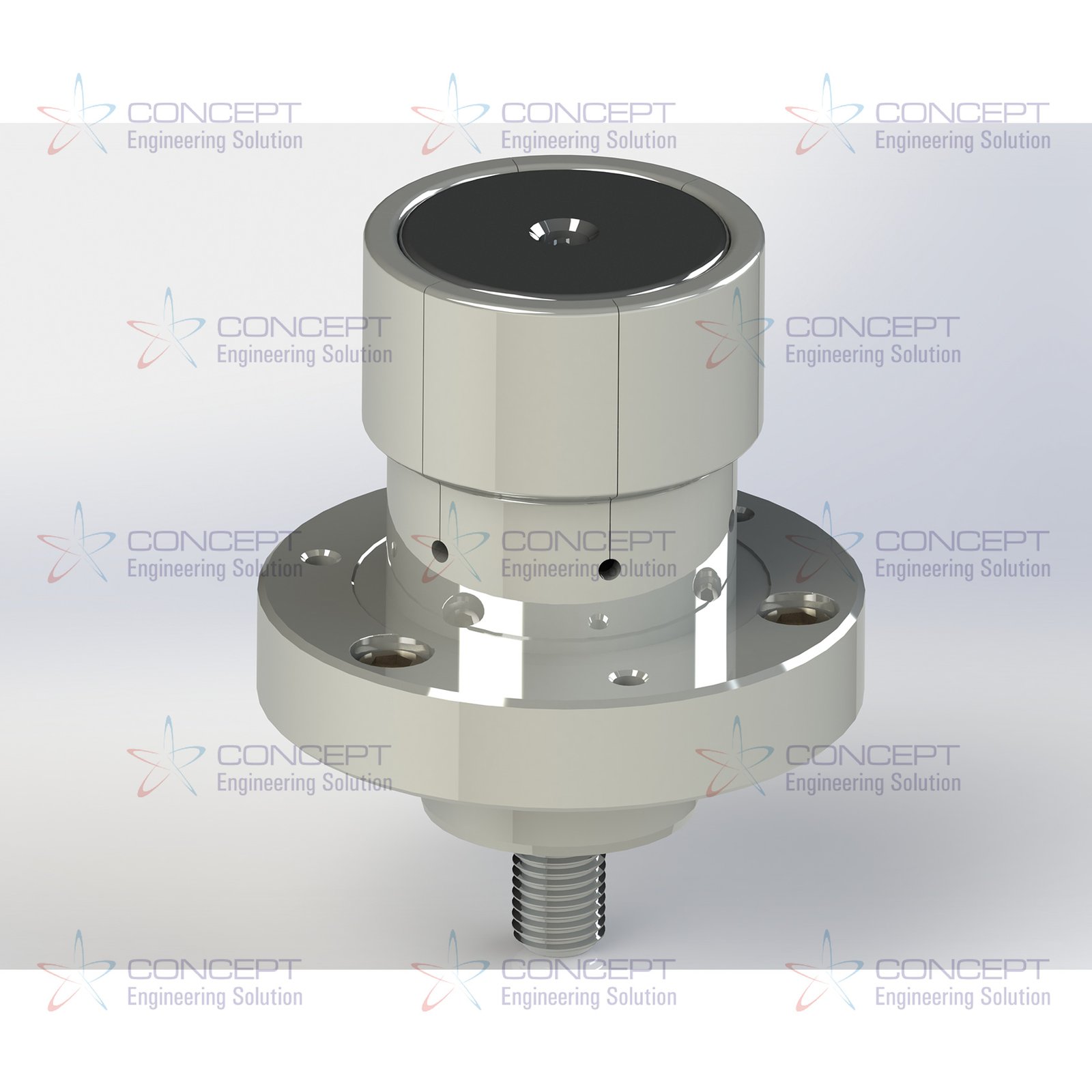

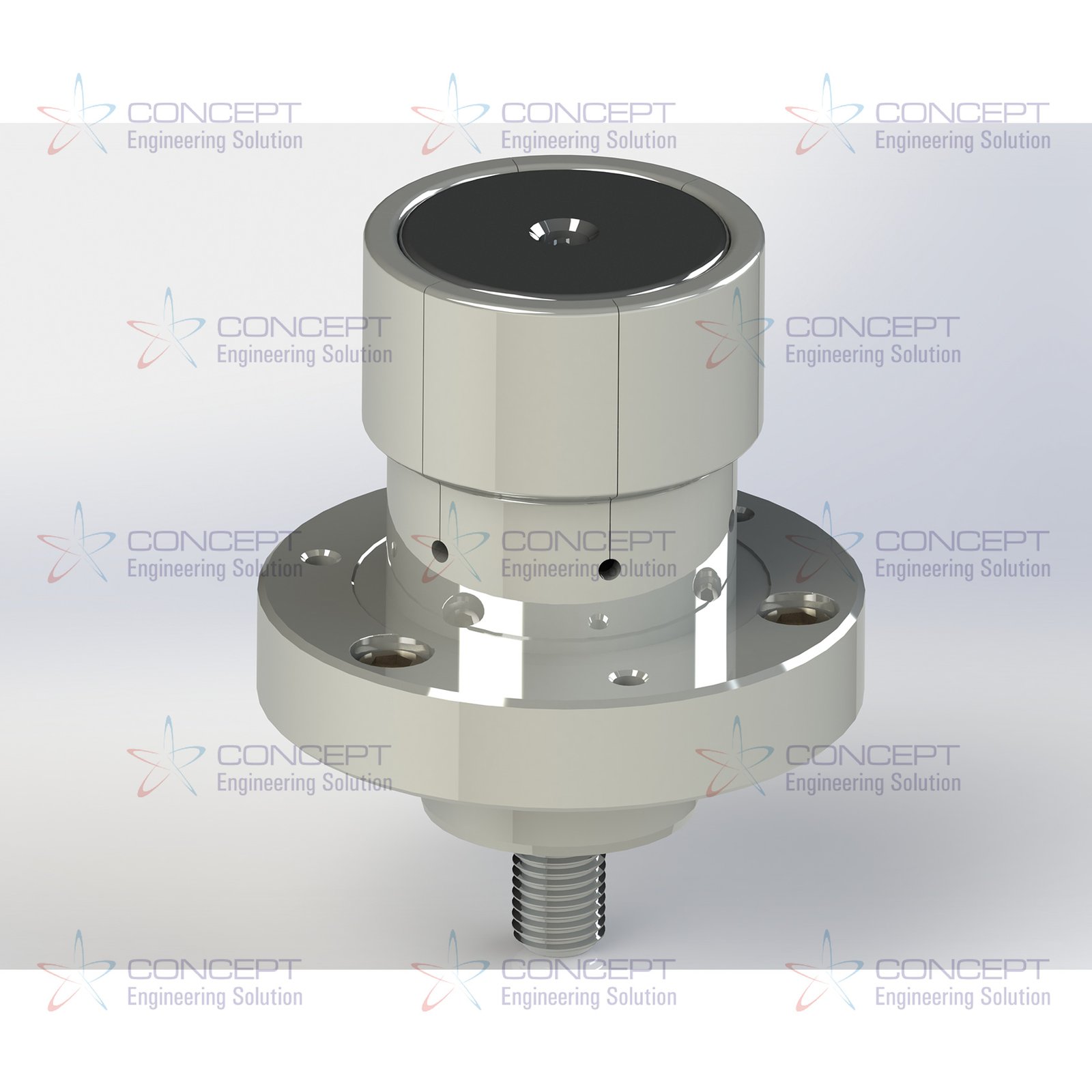

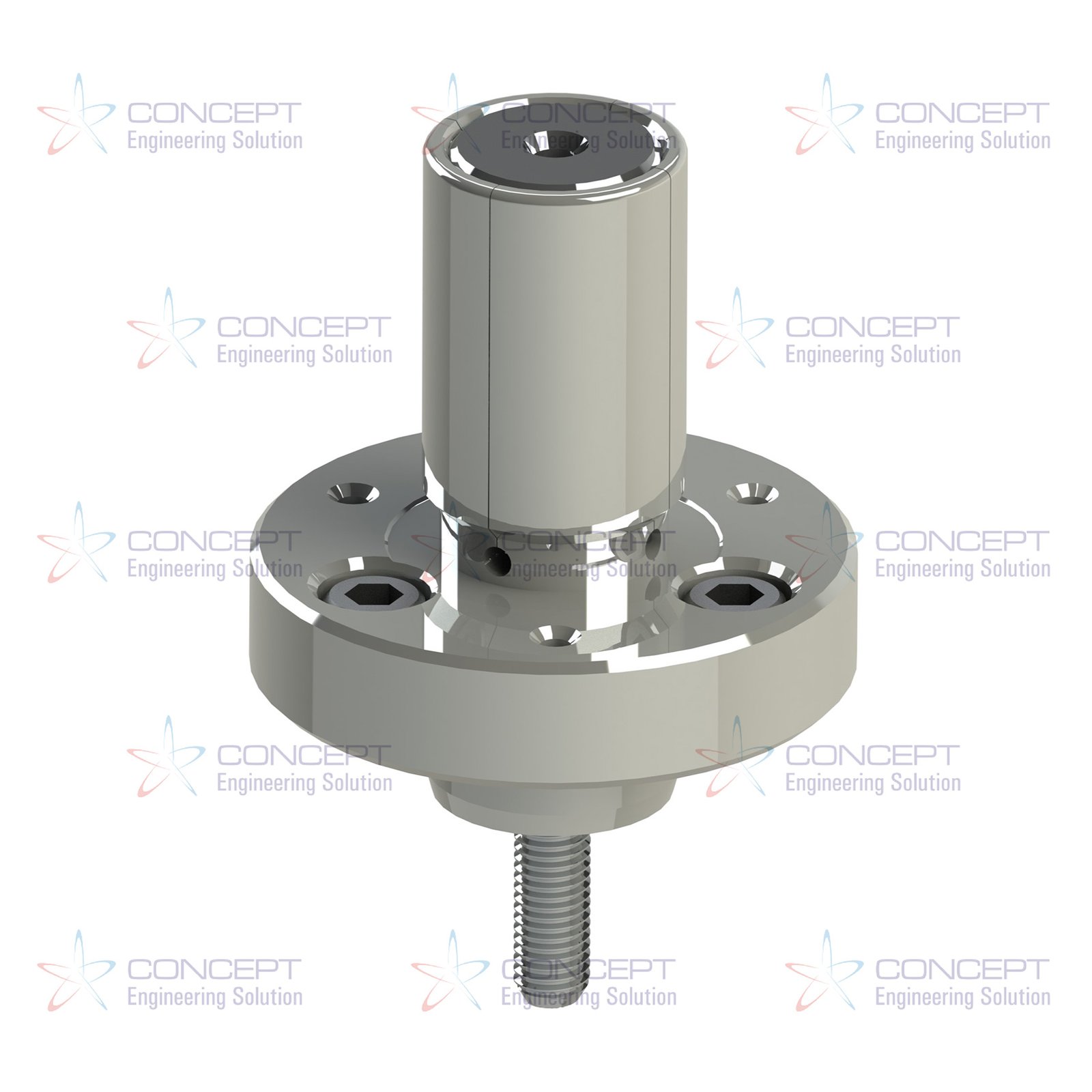

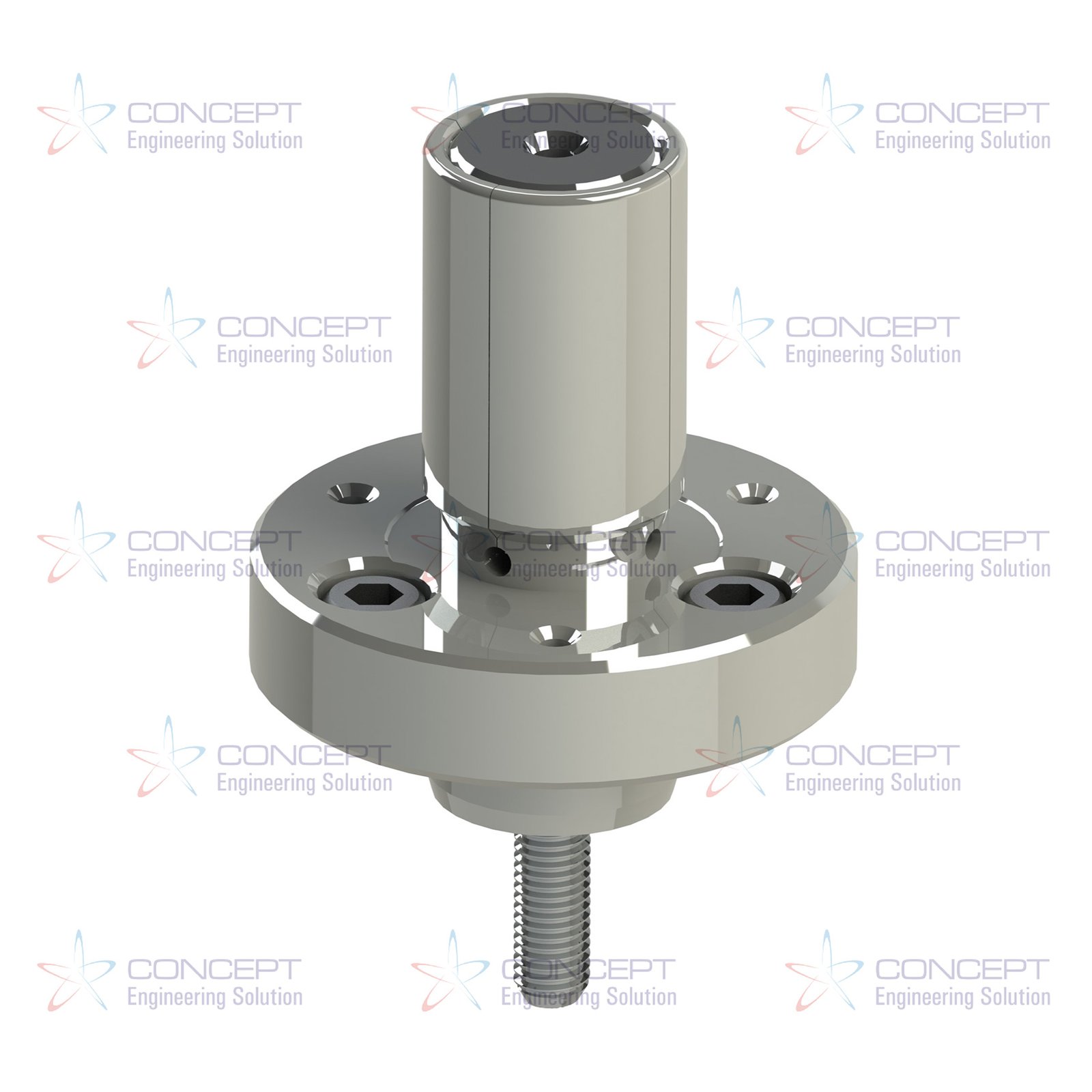

PULL-TYPE-COLLET-1

PULL-TYPE-COLLET-1

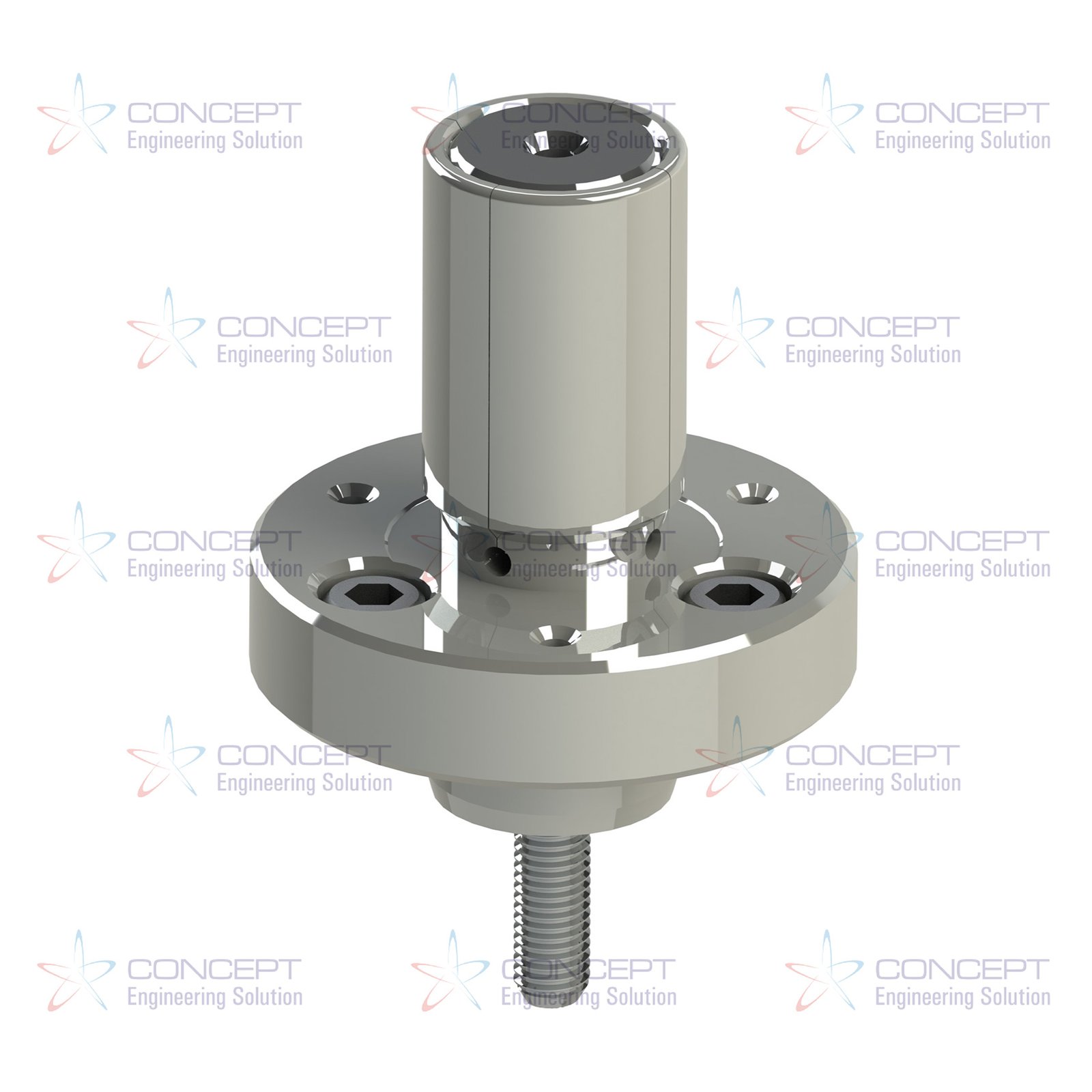

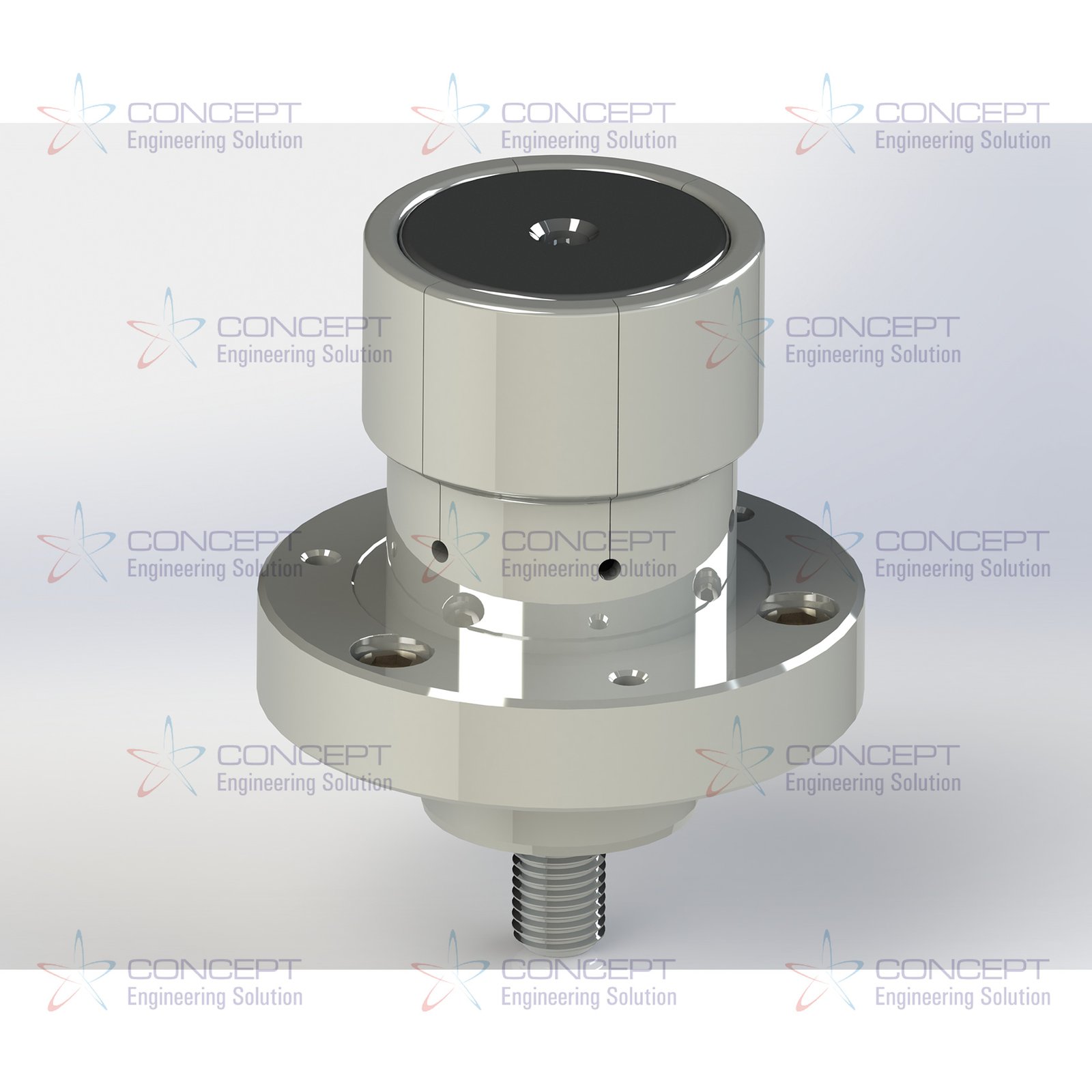

PULL-TYPE-COLLET-2

PULL-TYPE-COLLET-2

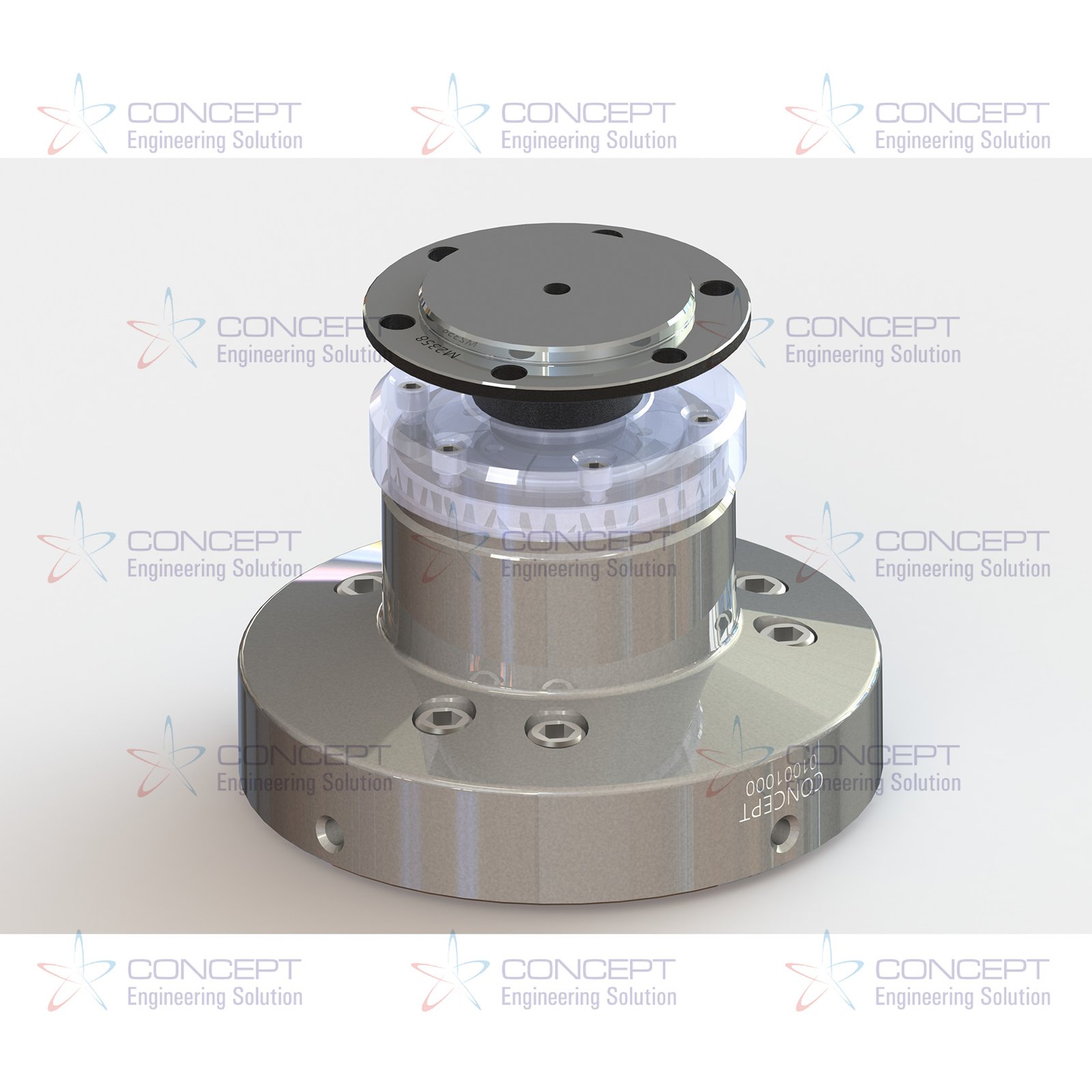

PULL-TYPE-COLLET-3

PULL-TYPE-COLLET-3

PUSH-TYPE-COLLET-1

PUSH-TYPE-COLLET-1

OD-COLLET

OD-COLLET

AIR-SEAT-COLLET

AIR-SEAT-COLLET

2-SIDE-SLIT

2-SIDE-SLIT

SERRATED-COLLET

SERRATED-COLLET

SERRATED-COLLET-1

SERRATED-COLLET-1